Expanding Into New Markets

The manufacturing industry can be extremely unpredictable. What works today might not be relevant tomorrow. Relying on one company or sector to keep your business afloat can put your business in serious jeopardy. The best way to protect your business from risk is to expand into new markets.

Protect Your Business from Risk

Building your business across several markets helps protect against unexpected circumstances. While losing a large customer can have a major impact on any business, it won’t completely disable your operations if you have other markets to fall back on.

When trying to determine which sectors to move into, it’s a good idea to look at what your competitors are doing. If certain sectors are being underserved, these are the areas you should pursue. If you are able to gain trust and successfully fill a demand, you’ll not only gain new customers, you’ll also prevent your competitors from being able to do the same.

How Contract Manufacturing Can Help

Companies responsible for the production of products often have difficulty expanding into new markets. These companies can benefit from hiring an experienced contract manufacturer.

Everyday, contract manufacturers help businesses bring new products to market. By using a contract manufacturer, businesses can experiment in new markets without having to worry about enormous start-up costs. If the venture successful, the business has been able to penetrate the market with relatively low risk.

A qualified contract manufacturer can help businesses provide high quality products for a variety of industries. This helps increase trust in your brand, which is crucial for market expansion. Businesses that make contract manufacturing a part of their long-term strategy outperform their competition time and time again.

Contract manufacturers can help with the design, production, and testing of new products. Contract manufacturers reduce time-to-market and increase the quality of products produced.

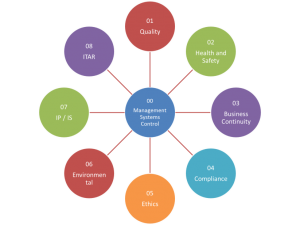

When choosing a contract manufacturer to work with, it’s important to ensure that the company you choose has experience with a variety of industries. You will also want to make sure that they have taken the time and effort necessary to achieve ISO certification. This helps ensure the production of consistent, high quality products.