Electronic devices must be able to perform in a variety of environments. This is especially true for electronic parts and components used by the medical, aerospace, and defense industries. Serious consequences can occur if electronic devices used by these industries fail.

Electronic devices must be able to perform in a variety of environments. This is especially true for electronic parts and components used by the medical, aerospace, and defense industries. Serious consequences can occur if electronic devices used by these industries fail.

Electronic Design

Reliable electronics begin with efficient design. Designers must consider the type of environment where finished products will be used. This helps determine the appropriate materials, components, packaging, and necessary cooling techniques.

Temperature Control

All electronic components are subject to failure due to overheating. Any increase in temperature can result in a reduced lifespan. This includes increase in temperature due to ambient temperature of the environment, heat produced by the device itself, and the product’s efficiency at heat removal.

There are numerous methods of temperature control. It’s important that designers and manufacturers consider these methods when creating new electronic devices and components. Common cooling techniques include free convection cooling, forced air cooling, and liquid cooling. Each method offers its own unique benefits. The type of cooling technique used will depend on a number of factors based around the intended use of the finished product.

Electronic Device Production

Organizations responsible for the creation of electronic parts and devices for the aerospace, medical, or defense industries must take care to ensure products do not fail due to excessive temperatures. This can be difficult to accomplish without the knowledge, experience, and equipment needed to test products in extreme environments.

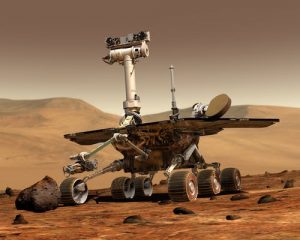

Partnering with a quality contract manufacturer can help these companies produce high quality products able to withstand even harsh conditions. Contract manufacturers provide a variety of services including design, production, and testing. At Means Engineering, our testing capabilities allow us to expose electronic parts and devices to a variety of environments. We can test products for reliability underwater, in space, and in extreme temperatures. This allows us to ensure that electronics do not fail when they are needed most.

Our designers can help you determine which cooling techniques your device requires. We have access to the latest tools, equipment, and technology. This makes it possible for us to produce reliable, long-lasting products for a variety of industries.

Organizations that wish to remain successful need to learn to work smarter not harder. This is easier said than done. Businesses often become stuck in their ways, unable to notice the opportunity for improvement. Creating a continuous improvement process can help. This process involves a number of ongoing activities focused on improving products, services, and/or processes.

Organizations that wish to remain successful need to learn to work smarter not harder. This is easier said than done. Businesses often become stuck in their ways, unable to notice the opportunity for improvement. Creating a continuous improvement process can help. This process involves a number of ongoing activities focused on improving products, services, and/or processes. Contract manufacturers create products under the name or brand of another business. Utilizing a contract manufacturer has numerous benefits. However, many companies struggle with the decision to outsource some or all of their production.

Contract manufacturers create products under the name or brand of another business. Utilizing a contract manufacturer has numerous benefits. However, many companies struggle with the decision to outsource some or all of their production. New technology is changing the way that people live and work. Consumers today expect more features and options than ever before. As consumer demand grows, connectivity is becoming more common in everyday devices.

New technology is changing the way that people live and work. Consumers today expect more features and options than ever before. As consumer demand grows, connectivity is becoming more common in everyday devices. Organizations responsible for the creation of products often struggle to maintain quality while keeping costs in check. This is especially true for organizations creating products for industries with strict requirements.

Organizations responsible for the creation of products often struggle to maintain quality while keeping costs in check. This is especially true for organizations creating products for industries with strict requirements.