Creating High Quality Medical Devices

The medical industry is constantly changing. New medical devices are created at an alarming rate. It’s crucial that the companies creating these devices are able to keep up with the latest technology. Medical devices perform a wide variety of extremely important jobs. Any malfunction or failure can be disastrous.

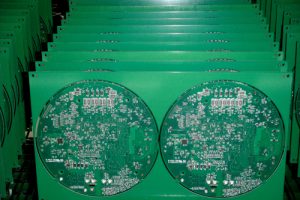

Medical devices are hardware or software used to treat human beings or diagnose disease. This also includes devices that have a profound effect on patient safety and risk management. Means Engineering, Inc. designs, creates and tests electronic devices for the medical industry. We strive to produce only the highest quality products. We are an ISO 13485-certified contract manufacturer. This ensures the durability and reliability of every product we produce.

Medical Device Regulations

It can be extremely difficult for companies to bring new products to market. This is especially true for medical devices, which must meet a wide range of regulatory standards. These standards are put in place to ensure that medical devices are safe and effective.

A thorough understanding of medical device regulations is crucial if companies wish to succeed in the medical industry. Most of these regulations revolve around Quality Management System (QMS) and risk management principles.

Regulations change rapidly. It’s up to the manufacturer to understand and implement all necessary changes. Using a contract manufacturer to handle the design and production of medical devices can help reduce costs and ensure compliance.

Contract manufacturers keep up with the latest technologies and techniques. They understand the various medical device regulations. They have the equipment, people and space necessary to consistently produce high quality products.

ISO 13485 Certified CM

ISO 13485 is the international standard for medical device manufacturers. Compliance with ISO 13485 helps minimize risk, reduce costs, increase customer satisfaction, increase sales and improve control over processes and internal systems. Certification also allows companies to access new markets and attract new clients.

Means Engineering offers contract manufacturing for a wide range of industries. We work directly with our clients to design, manufacture and test a variety of products. Please contact us for more information about medical device contract manufacturing services.