Companies need to launch new products to stay ahead of their competition. While a new product launch is an exciting time for your business, it’s not something you should rush into. Before launching a new product, take the time needed to learn what it takes to make the launch successful.

Companies need to launch new products to stay ahead of their competition. While a new product launch is an exciting time for your business, it’s not something you should rush into. Before launching a new product, take the time needed to learn what it takes to make the launch successful.

Research Your Target Audience

Prior to launch, you need to learn as much as you can about your target audience. Market research can help you develop an effective marketing plan. In fact, market research provides the foundation for all other steps in your product launch strategy.

When conducting market research, focus on learning what your target customers want and need and the most convenient distribution channels for your audience. Use the answers you receive to determine the best way to market your product. You might want to figure out which social media outlets your target customers use and whether they are more likely to purchase products based on logic or emotions.

Develop Your Message

Once you understand your target audience, you can develop your product messaging. This should include a solid value proposition. Make sure your messaging highlights the product’s best features and the problems they solve.

Promote Your Product Launch

Well planned and efficient promotion of your product launch ensures the success of your product. Create a product launch promotion strategy that educates your target audience and gets them excited about your product. This might include posting about your product launch on social media or through your company blog. Attending trade shows can also help promote your upcoming launch.

Plan for Post Launch

Your work isn’t finished once you’ve launched your product. You need to make sure you have a plan to maintain momentum and excitement after your launch. This is crucial to success. Your post launch plan should include tactics to keep your target audience engaged. This might include posts on social media, email marketing, and regular blog posts.

If you’re ready to create new products, Means Engineering Inc. can help. We have years of experience providing design, production, and testing of a wide range of products for numerous industries.

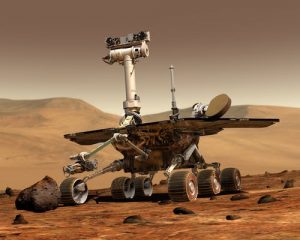

Electronic devices must be able to perform in a variety of environments. This is especially true for electronic parts and components used by the medical, aerospace, and defense industries. Serious consequences can occur if electronic devices used by these industries fail.

Electronic devices must be able to perform in a variety of environments. This is especially true for electronic parts and components used by the medical, aerospace, and defense industries. Serious consequences can occur if electronic devices used by these industries fail. Small businesses and entrepreneurs often seek help when creating electronic products. Many of these companies simply do not have the people, equipment, space, or technology needed to produce new products.

Small businesses and entrepreneurs often seek help when creating electronic products. Many of these companies simply do not have the people, equipment, space, or technology needed to produce new products. Companies today are under a lot of pressure to create high quality electronic products. Modern day consumers expect more features and options than ever before. In order to be successful, companies need to keep up with their competition. This means developing new products at an alarming rate.

Companies today are under a lot of pressure to create high quality electronic products. Modern day consumers expect more features and options than ever before. In order to be successful, companies need to keep up with their competition. This means developing new products at an alarming rate. At Means Engineering, we understand the importance of reliable and capable manufacturing services, especially when it comes to the Aerospace and Defense industries. Products for these industries must meet strict requirements for quality and reliability.

At Means Engineering, we understand the importance of reliable and capable manufacturing services, especially when it comes to the Aerospace and Defense industries. Products for these industries must meet strict requirements for quality and reliability.