Using a Contract Manufacturer for New Product Development

As a leading Southern California contract manufacturer, Means Engineering, Inc. has a lot of experience with new product development. We understand what’s important when looking for a company to design and build your product. We also know which details are essential to a positive experience.

Choosing a Contract Manufacturer

You have many options when it comes to selecting the company responsible for the design and build of your product. However, there are a few things that should be considered before partnering with a contract manufacturer.

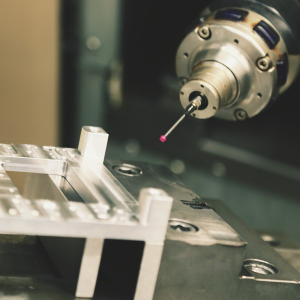

The contract manufacturer you choose needs to have the capability you require and should have multiple capabilities. Even if you do not think you need it now, it’s a good idea to select a company that has experience with a wide range of materials and processes. The company you choose should be able to provide engineering support. Having an experienced engineering team on your side can help you spot design flaws you might have missed. They can also suggest ways to reduce cost and time to market.

In order to ensure the highest quality, it’s crucial to select a contract manufacturer that is ISO certified. ISO standards are extremely strict in terms of quality control. Producing a part quickly and inexpensively does you absolutely no good if it does not meet quality standards.

Means Engineering, Inc. is ISO 9001, AS9100 and IOS 13485 certified. This ensures high quality products, time and time again.

Realistic Expectations

It’s not uncommon for companies to have unrealistic expectations when starting the product development process. Many companies underestimate the cost and time it will take for the product to go to market. Before assuming anything, it’s important to make sure that you have all of the facts.

Talk to your suppliers, vendors and contract manufacturers. They are in the best position to provide you with accurate cost and time to market estimates.

Final Thoughts

Before selecting a contract manufacturer for new product development, make sure that you check their references and view their previous work. Respectable companies will be happy to share this information with you.

Means Engineering, Inc. has extensive experience working with a variety of industries including the medical, industrial, semiconductor and defense industries. We provide smart, turnkey solutions and work directly with our clients from concept to completion.