New Product Development

New product development is a complex process involving multiple steps. Developing new electronic products requires a lot of time, experience, equipment, knowledge and technology. As such, it is often difficult for small businesses and start-ups to create new products. The following tips can help simplify the process.

Schematic Circuit Design

In order to create a printed circuit board (PCB), you must first produce a schematic circuit design. This provides the blueprint for your PCB. Designing a schematic circuit requires extensive knowledge of electronic devices.

It can helpful to have a second set of eyes look over the plans to see if there are any ways to improve the design or reduce the cost of development.

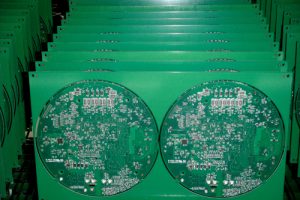

Printed Circuit Board Design

The next step involves the creation of a PCB layout. It is extremely easy to make errors during this process. Any mistakes made with power or RF circuits can negatively affect the performance of the finished product. Before beginning the PCB layout process, you will need to find out the specifications required by your PCB manufacturer.

Although a portion of the board might be automatically routed, most boards will still require some amount of manual routing. The software used to design the PCB should tell you whether or not your design matches the schematic.

Testing the Prototype

After receiving the first prototype, it will need to be tested and debugged. Issues are extremely common, yet difficult to predict. It’s impossible to know how long it will take to debug the prototype until it has been created and tested for defects.

Programming the Microcontroller

Most modern day electronics are equipped with a microcontroller. The microcontroller is crucial to the operation of these electronic devices. After debugging the PCB prototype, the microcontroller must be programmed. Someone with knowledge of computer language should be in charge of this step.

3D Modeling

3D modeling helps your product stand out from the competition. A 3D modeling expert can help make your product look good. Make sure that you work with someone that has experience with injection technology.

Creating new products is a complex process. A qualified contract manufacturer can help. Contract manufacturers provide a second set of eyes for your project. They can help with all aspects of new product creation from design and manufacture to testing.