Electronic devices must be able to perform in a variety of environments. This is especially true for electronic parts and components used by the medical, aerospace, and defense industries. Serious consequences can occur if electronic devices used by these industries fail.

Electronic devices must be able to perform in a variety of environments. This is especially true for electronic parts and components used by the medical, aerospace, and defense industries. Serious consequences can occur if electronic devices used by these industries fail.

Electronic Design

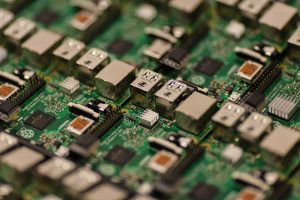

Reliable electronics begin with efficient design. Designers must consider the type of environment where finished products will be used. This helps determine the appropriate materials, components, packaging, and necessary cooling techniques.

Temperature Control

All electronic components are subject to failure due to overheating. Any increase in temperature can result in a reduced lifespan. This includes increase in temperature due to ambient temperature of the environment, heat produced by the device itself, and the product’s efficiency at heat removal.

There are numerous methods of temperature control. It’s important that designers and manufacturers consider these methods when creating new electronic devices and components. Common cooling techniques include free convection cooling, forced air cooling, and liquid cooling. Each method offers its own unique benefits. The type of cooling technique used will depend on a number of factors based around the intended use of the finished product.

Electronic Device Production

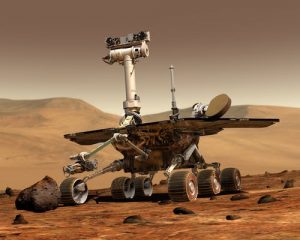

Organizations responsible for the creation of electronic parts and devices for the aerospace, medical, or defense industries must take care to ensure products do not fail due to excessive temperatures. This can be difficult to accomplish without the knowledge, experience, and equipment needed to test products in extreme environments.

Partnering with a quality contract manufacturer can help these companies produce high quality products able to withstand even harsh conditions. Contract manufacturers provide a variety of services including design, production, and testing. At Means Engineering, our testing capabilities allow us to expose electronic parts and devices to a variety of environments. We can test products for reliability underwater, in space, and in extreme temperatures. This allows us to ensure that electronics do not fail when they are needed most.

Our designers can help you determine which cooling techniques your device requires. We have access to the latest tools, equipment, and technology. This makes it possible for us to produce reliable, long-lasting products for a variety of industries.

Contract manufacturers provide a wide range of services. While your reasons for using a contract manufacturer can vary, it’s important that the relationship is beneficial to both parties. A contract manufacturer should provide your company with a variety of services designed to reduce costs and time to market.

Contract manufacturers provide a wide range of services. While your reasons for using a contract manufacturer can vary, it’s important that the relationship is beneficial to both parties. A contract manufacturer should provide your company with a variety of services designed to reduce costs and time to market. Custom electronic projects take a lot of special consideration. When outsourcing these projects, it’s important to have a clear understanding of your needs up front. These needs must be communicated with your contract manufacturer to ensure the project’s proper completion. It’s important to consider the following prior to outsourcing.

Custom electronic projects take a lot of special consideration. When outsourcing these projects, it’s important to have a clear understanding of your needs up front. These needs must be communicated with your contract manufacturer to ensure the project’s proper completion. It’s important to consider the following prior to outsourcing. Small businesses and entrepreneurs often seek help when creating electronic products. Many of these companies simply do not have the people, equipment, space, or technology needed to produce new products.

Small businesses and entrepreneurs often seek help when creating electronic products. Many of these companies simply do not have the people, equipment, space, or technology needed to produce new products. Companies today are under a lot of pressure to create high quality electronic products. Modern day consumers expect more features and options than ever before. In order to be successful, companies need to keep up with their competition. This means developing new products at an alarming rate.

Companies today are under a lot of pressure to create high quality electronic products. Modern day consumers expect more features and options than ever before. In order to be successful, companies need to keep up with their competition. This means developing new products at an alarming rate.