Machining in the Electronics Industry

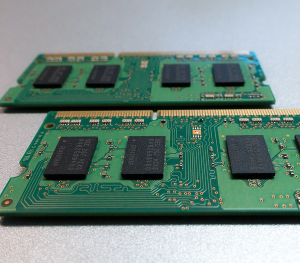

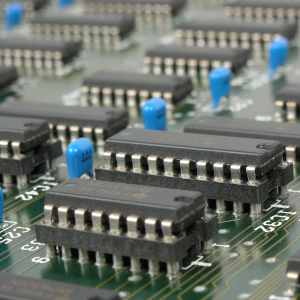

Modern electronic devices are smaller than ever before. In order to produce these products, electronics manufacturers must be able to create electronic components that are smaller, stronger, lighter and more powerful. This creates a unique challenge for manufacturers.

Electronics machining makes it possible to produce the high quality parts necessary to create modern electronic devices. Precise machining allows electronic components to be smaller, more reliable and stronger than previously possible.

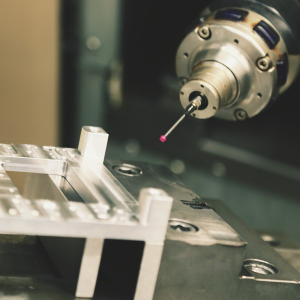

Tight Tolerance Precision Machining

Means Engineering, Inc. provides tight tolerance precision machining services. We are able to accommodate even the most stringent requirements. Our expert team is well prepared to solve a number of machining issues. We are able to produce parts that other companies cannot. We have the capabilities to handle a variety of volumes no matter how small, large or complex the project.

We offer our precision machining services to a variety of industries. Our expertise and first-rate equipment allows us to create high quality products from even the most complex designs. We offer prototypes, one offs and full production runs. We have experience working with a wide range of industries including aerospace, medical, semiconductor and defense. We are able to quickly and efficiently produce quality parts that meet and exceed the expectations of our clients.

High Quality, Reliable Parts

Every year, the electronics manufacturing industry faces more pressure to produce better, faster and stronger products. This is especially true for the semiconductor industry. In order to remain successful and competitive in the marketplace, companies need to be able to meet the growing needs of their customers.

Since our expert staff has extensive experience with the machining process, we are able to evaluate plans before any manufacturing takes place. This puts us in the best possible position to address areas of concern before production. This helps us ensure that our customers receive high quality parts time and time again.

Means Engineering, Inc. is able to handle a wide variety of projects regardless of their size, material or quantity requirements. We maintain ISO 9001 and AS 9100 certification. This ensures you receive the best quality available today.