Cyber-attacks are on the rise. Attacks are becoming more sophisticated putting organizations of all shapes and sizes at risk. It’s important that organizations learn all they can about the risks of cyber-attacks and how to avoid becoming a victim.

Cyber-attacks are on the rise. Attacks are becoming more sophisticated putting organizations of all shapes and sizes at risk. It’s important that organizations learn all they can about the risks of cyber-attacks and how to avoid becoming a victim.

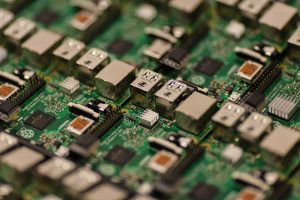

Several industries have implemented rules and regulations to help address the rise of cyber-attacks. These regulations aim to increase the security of electronic devices to prevent attackers from gaining access to sensitive information. This is especially important for organizations creating products for the defense and medical industries.

Companies that produce products for the military must take care to ensure that products comply with the International Trafficking in Arms Regulations (ITAR) and other compliance standards. Organizations that do not ensure compliance of all of the products and components face multi-million dollar fines and possible jail time.

Ensuring ITAR Compliance

Any company that manufactures, sells or distributes goods or services covered under the United States Munitions List (USML) must be registered with the State Department’s Directorate of Defense trade Controls (DDTC). These companies must understand and abide by the ITAR as it applies to their USML linked goods or services.

Unfortunately, many businesses fail to meet compliance with the ITAR. This is often due to the fact that ITAR is full of complications that make it easy for companies to make mistakes.

It’s important that organizations take the time necessary to ensure proper licensing of all of the products they produce. These organizations need to invest in training someone in-house to handle the complex compliance process.

Partnering With an Experienced Contract Manufacturer

Organizations that do not have the time, knowledge, or resources needed to ensure compliance can benefit from partnering with an experienced contract manufacturer.

Contract manufacturers understand complex regulation requirements. They have the people and processes in place to ensure compliance with a number of industry standards. Means Engineering has extensive experience designing and producing parts and products for the defense industry. Our team ensures compliance with ITAR and other industry regulations. This protects your company from costly fines, and protects users from cyber-attacks.

Contract manufacturers provide a wide range of services. While your reasons for using a contract manufacturer can vary, it’s important that the relationship is beneficial to both parties. A contract manufacturer should provide your company with a variety of services designed to reduce costs and time to market.

Contract manufacturers provide a wide range of services. While your reasons for using a contract manufacturer can vary, it’s important that the relationship is beneficial to both parties. A contract manufacturer should provide your company with a variety of services designed to reduce costs and time to market. Custom electronic projects take a lot of special consideration. When outsourcing these projects, it’s important to have a clear understanding of your needs up front. These needs must be communicated with your contract manufacturer to ensure the project’s proper completion. It’s important to consider the following prior to outsourcing.

Custom electronic projects take a lot of special consideration. When outsourcing these projects, it’s important to have a clear understanding of your needs up front. These needs must be communicated with your contract manufacturer to ensure the project’s proper completion. It’s important to consider the following prior to outsourcing. Companies everywhere strive to keep costs low. Reducing costs on manufacturing increases profits and allows for better allocation of funds. When looking into ways to cut costs, one of the decisions business owners should consider is whether or not to outsource some or all of their production.

Companies everywhere strive to keep costs low. Reducing costs on manufacturing increases profits and allows for better allocation of funds. When looking into ways to cut costs, one of the decisions business owners should consider is whether or not to outsource some or all of their production. Product testing is important for a number of reasons. Testing allows an organization to ensure the quality of new products before they go to market. It also helps locate areas that could benefit from improvement. Fixing these issues before products hit the shelf helps prevent possible loss of customers and reputation.

Product testing is important for a number of reasons. Testing allows an organization to ensure the quality of new products before they go to market. It also helps locate areas that could benefit from improvement. Fixing these issues before products hit the shelf helps prevent possible loss of customers and reputation.