Benefits of Contract Manufacturing

A contract manufacturer creates products and their components under the label or brand of the companies that hire them. Contract manufacturing is an excellent option for companies that wish to increase their product line but do not have the staff or resources necessary to do so. Contract manufacturing is used to create products for a wide range of industries. It has a number of benefits for companies of all shapes and sizes.

Contract Manufacturing Saves Time

Hiring a contract manufacturer can save a company a considerable amount of time and resources. Companies that use contract manufacturing services do not have to go through the lengthy process of hiring and training new employees to fulfill orders. They do not need to locate a new facility or obtain the equipment necessary for production. The contract manufacturer provides everything needed to produce high quality products. This provides more time for managers to focus on other important aspects of their business.

Contract Manufacturing Saves Money

Perhaps the biggest benefit of contract manufacturing is the cost savings. Companies that hire a contract manufacturer save money on equipment, facility fees and additional employees. In addition, contract manufacturers are typically able to produce parts at a fraction of the cost of in-house production. Contract manufacturing is ideal for the development and testing of new products. A contract manufacturer can also be useful in fulfilling orders when demand for a specific product is high.

High Quality Products

It takes a lot of training and experience to create high quality products. This type of expertise isn’t always feasible when producing products in-house. Sensitive parts, such as those used in electronic devices must be created in a cleanroom environment. This prevents contamination which can affect the reliability of the finished product. A contract manufacturer has the training, experience, equipment and quality control processes necessary to create high quality, reliable products time and time again.

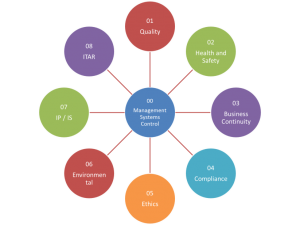

When selecting a contract manufacturer to work with, consider a company that has experience working with a number of different industries. They should have a Quality Management System registered to ISO 9001 and AS 9100.