“Going Green” – What it Means for Electronics Manufacturing

“Going green” means to learn about and utilize practices that lead to environmentally friendly decisions with the ultimate intention of protecting our environment and our resources for future generations. Going green is becoming more and more important every day.

Improper Disposal of E-Waste Creates a Number of Environmental Problems

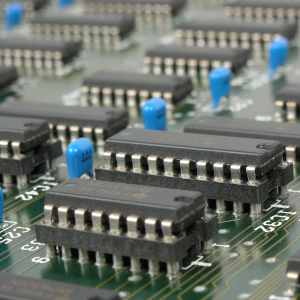

When electronic devices end up in our landfills, toxic substances such as lead, mercury and cadmium leach into our soil, eventually contaminating our groundwater. Electronic waste must be disposed of properly in order to protect our environment from these harmful substances.

The toxic materials found in electronic devices are not only harmful for our environment, but also for the workers creating these products. Green electronics manufacturing seeks to reduce the amount of harmful substances used in electronic devices, and the risks associated with them.

Challenges Faced By Electronics Manufacturers

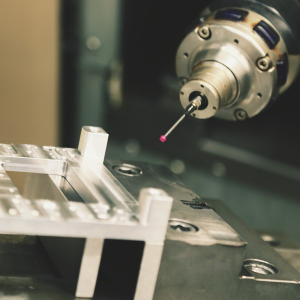

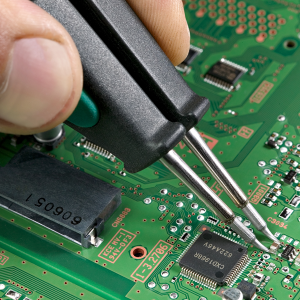

Electronics manufacturers are now faced with the unique challenge of designing, developing, building and installing electronics while paying special attention to the product’s environmental impact throughout its entire lifecycle.

Manufacturing electronics creates a lot of waste. Electronics manufacturers are encouraged to reduce the amount of e-waste by designing products that minimize the amount of harmful substances used and by recycling and reusing as much as possible. Green manufacturing also includes the manufacture of products with longer lifecycles. This helps further reduce the amount of e-waste created by the electronics industry.

Green manufacturing focuses on reducing parts, rationing materials and reusing components. When done right, green manufacturing allows electronics manufacturers to create environmentally friendly products while maintaining the same quality and reliability of the electronics they produce.

Consumer Responsibility

More than twenty million tons of e-waste is produced every single year. The U.S. alone produces 3.4 million tons per year. Electronic waste makes up as much as 5% of the world’s municipal solid waste.

Consumers are encouraged to dispose of e-waste properly. Computers, cell phones and household electronics should never be disposed of with regular trash. Most cities have special waste management services to handle e-waste. It’s important to check local guidelines regarding the proper disposal of e-waste.