Every business owner has the dream of creating the perfect product. However, making this dream a reality is often much harder than believed. Taking an idea from prototype to production can take years of expensive trial and error for companies that attempt to handle the manufacturing themselves.

Every business owner has the dream of creating the perfect product. However, making this dream a reality is often much harder than believed. Taking an idea from prototype to production can take years of expensive trial and error for companies that attempt to handle the manufacturing themselves.

Sometimes companies find they simply do not have the people or resources needed to keep up with demand. This is especially true for organizations responsible for the creation of electronic parts and components.

For most businesses, giving up simply isn’t an option. These businesses can benefit significantly from enlisting the help of a qualified contract manufacturer.

Experienced contract manufacturers have the tools, equipment, and knowledge needed to create high quality products. These companies often have years of experience and employ industry experts, each prepared to provide their assistance if the project requires. Contract manufacturers take extra care to ensure products are completed to exact specifications and requirements. When involved in the design process, they can even suggest ways to reduce costs and increase the quality of the finished project.

There are a few things you’ll need to consider before seeking the help of a contract manufacturer:

Will People Buy Your Product?

Perform market research or ask people through social media whether they would be interested in your product. This can help ensure you create something consumers actually want. Consider asking your contract manufacturer what they think of your product. Accept their suggestions for adding or removing features to improve the functionality of your product. Remember, these are industry experts with years of experience.

Design Improvements

Even if you’re absolutely sure your audience will want your product, it’s always a good idea to have your contract manufacturer look over your design plans. As mentioned before, an experienced contract manufacturer will know how to make improvements that could end up saving you a lot of time, money, and hassle in the future.

Choose a Partner Over a Provider

The right contract manufacturer will ensure a long-lasting relationship with their clients. This is mutually beneficial for both parties. Select a contract manufacturer that can help your business grow and expand over time.

Companies need to launch new products to stay ahead of their competition. While a new product launch is an exciting time for your business, it’s not something you should rush into. Before launching a new product, take the time needed to learn what it takes to make the launch successful.

Companies need to launch new products to stay ahead of their competition. While a new product launch is an exciting time for your business, it’s not something you should rush into. Before launching a new product, take the time needed to learn what it takes to make the launch successful. Cyber-attacks are on the rise. Attacks are becoming more sophisticated putting organizations of all shapes and sizes at risk. It’s important that organizations learn all they can about the risks of cyber-attacks and how to avoid becoming a victim.

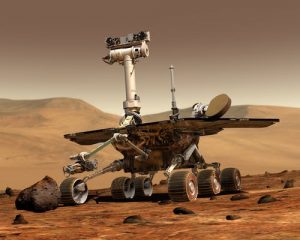

Cyber-attacks are on the rise. Attacks are becoming more sophisticated putting organizations of all shapes and sizes at risk. It’s important that organizations learn all they can about the risks of cyber-attacks and how to avoid becoming a victim. Electronic devices must be able to perform in a variety of environments. This is especially true for electronic parts and components used by the medical, aerospace, and defense industries. Serious consequences can occur if electronic devices used by these industries fail.

Electronic devices must be able to perform in a variety of environments. This is especially true for electronic parts and components used by the medical, aerospace, and defense industries. Serious consequences can occur if electronic devices used by these industries fail. Custom electronic projects take a lot of special consideration. When outsourcing these projects, it’s important to have a clear understanding of your needs up front. These needs must be communicated with your contract manufacturer to ensure the project’s proper completion. It’s important to consider the following prior to outsourcing.

Custom electronic projects take a lot of special consideration. When outsourcing these projects, it’s important to have a clear understanding of your needs up front. These needs must be communicated with your contract manufacturer to ensure the project’s proper completion. It’s important to consider the following prior to outsourcing.