IPC Standards and Their Role in PCB Manufacturing

Strict quality control is extremely important to the manufacture and design of printed circuit boards. Any defect can negatively affect the operation and reliability of the PCB. Since PCBs are typically produced in bulk, just one defect has the potential to render dozens of PCBs ineffective.

PCBs and Modern Technology

Thanks to technological advances, PCBs are able to perform more functions than ever before. These important electronic components can be designed and produced inexpensively, making it possible for manufacturers to install complex electronic components inside affordable household devices.

Printed circuit boards are used in almost every modern day electronic. The quality of the PCB has a significant impact on how these electronic devices perform. This is why it’s crucial that every PCB meets or exceeds industry standards.

PCB Failure Could Have Devastating Results

The function and reliability of PCBs is crucial to the overall success of the final product. There are a number of situations where PCB failure could be devastating. Apart from being more costly, faults in the design and manufacture of PCBs could result in system failure, compensation claims or worse. It’s extremely important that steps are taken to avoid defects during the PCB’s design and manufacturing process.

IPC Standards

The Institute for Printed Circuit Boards (IPC) is the global trade association for the electronics industry. In order to ensure the consistent quality of electronic devices, the IPC has set certain standards for the design and manufacture of all printed circuit boards as well as other electronics components.

Means Engineering Inc. strives to meet or exceed IPC standards for PCB design and manufacture. This ensures high quality products that perform exactly as they should time and time again.

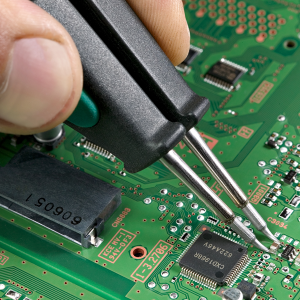

Cleanroom Assembly

PCBs contain delicate parts that are easily damaged by contamination. Even microscopic particles can cause a big problem. Means Engineering Inc. follows strict cleanliness procedures to ensure the most reliable products.

When high quality PCBs are assembled in a cleanroom environment, this effectively mitigates the chance of contamination. Our high quality products exceed the cleanliness requirements set by the IPC.