Producing products takes a lot of skill, experience, equipment, and technology. While many business owners have excellent ideas for creating new products, they often do not have the money or resources needed to bring them to market. These companies turn to contract manufacturers to produce part or all of their products. A contract manufacturer creates products under the name or brand of the company that hires them. CMs generally offer a variety of services related to the design, production, and testing of products for a wide range of industries.

Producing products takes a lot of skill, experience, equipment, and technology. While many business owners have excellent ideas for creating new products, they often do not have the money or resources needed to bring them to market. These companies turn to contract manufacturers to produce part or all of their products. A contract manufacturer creates products under the name or brand of the company that hires them. CMs generally offer a variety of services related to the design, production, and testing of products for a wide range of industries.

There are many benefits to partnering with a contract manufacturer. Below we discuss the top three:

Improve Product Quality

The quality of finished products says a lot about your business. It’s important to ensure all products produced meet or exceed your customers’ expectations. Unfortunately, many companies do not know what it takes to create high quality products. These companies can benefit from partnering with a contract manufacturer.

A contract manufacturer provides a second set of eyes for your design plans. This helps locate areas that could benefit from improvement. Your audience is sure to appreciate the extra time and attention to detail a contract manufacturer takes to ensure the production of high quality, reliable parts and products.

Decrease Costs

In addition to improving product quality, a CM can help discover ways to reduce the cost of production. This might mean switching a type of material or changing a measurement slightly. Whatever the case, your CM can decrease the costs associated with production and logistics.

One of the biggest benefits of working with a CM is that it eliminates the need to purchase or maintain your own facility, equipment, and technology. This saves your company a considerable amount of money over producing products in-house.

Reduce Time to Market

Taking a product from idea to reality takes a lot of trial and error. When you work with an experienced contract manufacturer they can help you get it right in less time than it would take to complete the task yourself. Utilizing the help of an experienced CM allows you to create more products in less time.

Contract manufacturers provide a variety of services to businesses across a wide range of industries. When it comes to the medical industry, you must take care to ensure that everyone understands the rules and regulations surrounding medical device creation. Humans often rely on these devices for their health, safety, and well-being. If the device fails, it can lead to serious consequences.

Contract manufacturers provide a variety of services to businesses across a wide range of industries. When it comes to the medical industry, you must take care to ensure that everyone understands the rules and regulations surrounding medical device creation. Humans often rely on these devices for their health, safety, and well-being. If the device fails, it can lead to serious consequences. The right contract manufacturer can help your business grow and expand into new markets. A CM acts as your partner, providing a number of services designed to compliment your business and improve customer satisfaction with your brand. Unfortunately, many people go into this partnership with unrealistic expectations. This is due in part to the large number of myths about working with a contract manufacturer. We have listed the top three myths and why you shouldn’t believe what you hear. This is important if you want a successful relationship with your CM.

The right contract manufacturer can help your business grow and expand into new markets. A CM acts as your partner, providing a number of services designed to compliment your business and improve customer satisfaction with your brand. Unfortunately, many people go into this partnership with unrealistic expectations. This is due in part to the large number of myths about working with a contract manufacturer. We have listed the top three myths and why you shouldn’t believe what you hear. This is important if you want a successful relationship with your CM. Cyber-attacks are on the rise. Attacks are becoming more sophisticated putting organizations of all shapes and sizes at risk. It’s important that organizations learn all they can about the risks of cyber-attacks and how to avoid becoming a victim.

Cyber-attacks are on the rise. Attacks are becoming more sophisticated putting organizations of all shapes and sizes at risk. It’s important that organizations learn all they can about the risks of cyber-attacks and how to avoid becoming a victim. Electronic devices must be able to perform in a variety of environments. This is especially true for electronic parts and components used by the medical, aerospace, and defense industries. Serious consequences can occur if electronic devices used by these industries fail.

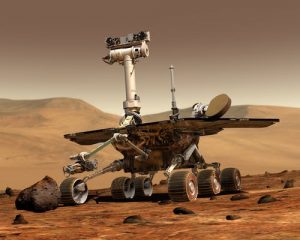

Electronic devices must be able to perform in a variety of environments. This is especially true for electronic parts and components used by the medical, aerospace, and defense industries. Serious consequences can occur if electronic devices used by these industries fail.