Sustainability Drives Innovation in 2018

Increased sustainability becomes more important every year. As the public becomes aware of the growing environmental concerns regarding electronic products and the way they are produced, manufacturing companies are faced with mounting pressure to improve their operations and produce greener products. However, many manufacturing companies worry that increased sustainability will cost too much and do little for their bottom line. This simply isn’t true.

In order to increase sustainability, manufacturing companies must develop a series of organizational and technological innovations. When done right, these improvements can increase both bottom line and top line returns.

Reducing Costs

Becoming more sustainable reduces costs by limiting the amount of inputs used. In addition to saving money, sustainable practices produce better products, increasing revenue and opening the door for new business. The smartest companies have already adopted sustainable practices.

In order to remain competitive, companies need to change the way they think about products, technologies, processes and business models. Companies that are able to adopt sustainability today will be untouchable in the future. Sustainable companies will always have the competitive edge, as sustainability is an integral part of development.

Increasing Sustainability

Sustainability starts with accountability. Manufacturing companies wishing to gain a competitive edge cannot simply strive to adhere to the lowest environmental standards. The best manufacturing companies adhere to only the strictest rules. By producing products by standards that are not yet enforced, a company can stay ahead of their competition in terms of both quality and sustainability.

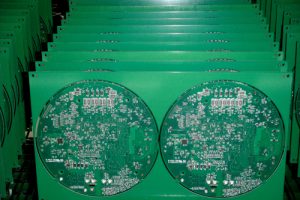

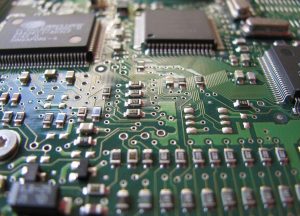

In order to create more sustainable products and improve business operations, electronics companies might need to purchase new equipment and adopt new technologies. This is often difficult for start-ups and smaller companies. These companies simply do not have the resources necessary to increase sustainability. Outsourcing can be an excellent option in these types of situations.

Contract manufacturers keep up-to-date with the latest technologies and techniques. They have the equipment and people necessary to produce high quality products. Outsourcing enables electronic companies to gain a competitive edge without purchasing expensive equipment or the space needed for production. Outsourcing reduces costs and time to market while increasing quality and sustainability.

Top Challenges Faced by Electronics Manufacturers

Top Challenges Faced by Electronics Manufacturers